Uvod

This manual provides essential information for the safe and effective use of the Carrier HK42FZ027 OEM Replacement Furnace Control Board. This high-quality component is designed to replace original equipment manufacturer (OEM) furnace control boards in compatible Carrier furnace systems, ensuring proper operation and control of your heating system.

Varnostne informacije

Pomembna varnostna navodila

- DANGER: Electrical Shock Hazard. Disconnect all power to the furnace at the main service panel before installing or servicing this control board. Failure to do so can result in serious injury or death.

- Qualified Personnel Only. Namestitev in servisiranje naj izvaja samo usposobljen tehnik HVAC.

- Static Discharge Precautions. Electronic components are sensitive to static electricity. Handle the control board by its edges and use appropriate electrostatic discharge (ESD) precautions.

- Verify Compatibility. Ensure this control board (HK42FZ027) is the correct replacement part for your specific furnace model before installation.

- Wiring Accuracy. Double-check all wiring connections against the furnace's wiring diagram to prevent damage to the control board or furnace.

Konec izdelkaview

Identifikacija komponente

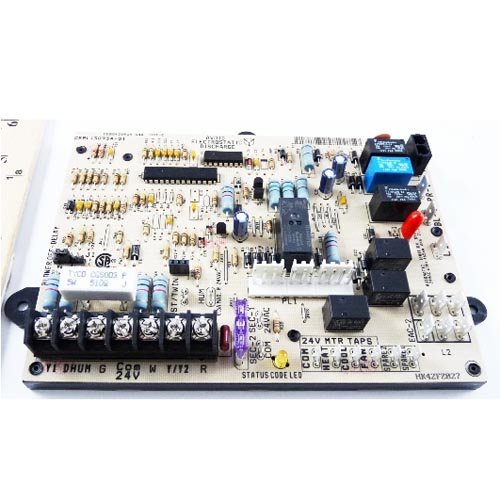

The Carrier HK42FZ027 furnace control board is the central processing unit for your furnace, managing various functions such as ignition, fan operation, and safety limits. Below is an image of the control board with key areas and components visible.

Opis slike: This image displays the Carrier HK42FZ027 furnace control board. The board is a rectangular circuit board populated with various electronic components including relays (blue and black rectangular components), capacitors (cylindrical components), resistors, and integrated circuits. Prominent features include:

- A terminal block for low-voltage thermostat wiring (labeled Y1, DHUM, G, C, W, Y/Y2, R).

- A status code LED for diagnostic indications.

- 24V motor taps (labeled COM, HEAT, COOL, FA, SPARE).

- Additional terminals for EAC-2 and L2.

- Various labels such as "ST/TWIN", "HUM", "SEC-2 SEC-Y COM 24VAC" indicating specific functions or connections. The model number "HK42FZ027" is clearly visible on the board.

Nastavitev in namestitev

Postopek namestitve

Follow these steps carefully when installing the replacement control board. Always prioritize safety.

- Odklop napajanja: Turn off all electrical power to the furnace at the main service panel and at the furnace's local disconnect switch.

- Odstranitev dostopne plošče: Remove the furnace access panel to expose the existing control board.

- Ožičenje dokumentov: Carefully photograph or sketch the existing wiring connections to the old control board. Label all wires for accurate re-connection. This step is crucial for correct installation.

- Odklopite žice: Odklopite vse žice s stare krmilne plošče.

- Odstranite staro ploščo: Unmount the old control board from the furnace chassis.

- Namestitev nove plošče: Mount the new Carrier HK42FZ027 control board in the same location, ensuring it is securely fastened.

- Ponovno priklop ožičenja: Reconnect all wires to the new control board according to your documentation. Double-check every connection for accuracy.

- Varne plošče: Replace the furnace access panel.

- Obnovi moč: Ponovno vzpostavite električno napajanje peči.

- Testno delovanje: Initiate a heating or cooling cycle to verify proper furnace operation. Observe the status code LED for any diagnostic indications.

Opomba: If you are unsure about any step, consult a qualified HVAC technician. Improper installation can lead to equipment damage or personal injury.

Načela delovanja

How the Control Board Functions

The HK42FZ027 control board acts as the central processing unit of your furnace system. It receives signals from the thermostat and various safety devices to control the sequence of operations, ensuring efficient and safe heating. Key functions include:

- Zaporedje vžiga: Manages the precise timing and execution of the burner ignition process.

- Delovanje ventilatorja: Controls the indoor blower fan for heating, cooling, and continuous fan modes based on thermostat demands.

- Varnostni nadzor: Continuously monitors various safety limits (e.g., high temperature, flame sensor) and initiates a safety shutdown if a fault is detected, often indicated by the status code LED.

- Accessory Control: May manage auxiliary components such as humidifiers or electronic air cleaners connected to specific terminals on the board.

Vzdrževanje

Nega in pregled

The control board itself is a sealed electronic component and requires minimal direct maintenance. However, regular inspection of the overall furnace system is recommended to ensure its longevity and proper function.

- Letni pregled: Have a qualified HVAC technician inspect your furnace annually. This inspection should include checking the control board and its connections for any signs of wear, corrosion, or loose wiring.

- Čistoča: Ensure the area around the control board is kept free from excessive dust and debris, which can impede airflow and component cooling.

- Izogibajte se vlagi: Keep the control board and the entire furnace area dry to prevent electrical shorts and corrosion.

Odpravljanje težav

Common Issues and Diagnostics

The status code LED on the control board provides valuable diagnostic information. When a fault occurs, the LED will flash a specific sequence. Refer to your furnace's specific service manual for a complete list of flash codes and their corresponding meanings.

- Brez napajanja: Check circuit breakers and the furnace disconnect switch. Ensure all wiring connections to the control board are secure.

- Peč se ne zažene: Verify thermostat settings. Check for error codes on the status LED. Ensure the gas supply is on and the igniter is functioning.

- Ventilator ne deluje: Check thermostat fan settings. Look for fan-related error codes on the status LED.

- Občasno delovanje: This can indicate a loose connection, a failing sensor, or an intermittent fault on the board. Consult a qualified technician for diagnosis.

Opozorilo: Do not attempt to repair the control board yourself. Replacement by a qualified technician is recommended for faulty boards.

Specifikacije

Specifikacije izdelka

| Funkcija | Podrobnost |

|---|---|

| Številka modela | HK42FZ027 |

| Znamka | Carrier (OEM Replacement) |

| Dimenzije izdelka | 6 x 6 x 6 palcev |

| Teža predmeta | 13 unč |

| Proizvajalec | Nosilec |

| ASIN | B00FPOQWPI |

Garancija in podpora

Informacije o garanciji

Specific warranty details for this OEM replacement part may vary depending on the seller and the date of purchase. Please refer to your purchase documentation or contact the seller directly for warranty terms and conditions.

Tehnična podpora

For technical assistance or further inquiries regarding the Carrier HK42FZ027 control board, it is recommended to contact a qualified HVAC professional. For official product support, please refer to the original equipment manufacturer (Carrier) documentation or website for their authorized support channels.